The Keihin Carburetor Manual PDF is a comprehensive guide essential for mechanics and enthusiasts, covering setup, troubleshooting, and maintenance. It helps optimize engine performance and is suitable for all skill levels.

1.1 Overview of the Keihin Carburetor

The Keihin carburetor is a precision-engineered component designed to regulate air-fuel mixture in internal combustion engines. Known for reliability and performance, it features components like the throttle valve, main jet, and pilot jet. The carburetor ensures proper fuel delivery at various engine speeds, from idle to high RPM. Its design allows for adjustments to optimize performance, making it a popular choice for motorcycles and small engines. Understanding its operation is crucial for effective tuning and troubleshooting, as outlined in the manual.

1.2 Importance of the Manual for Maintenance and Repair

The Keihin carburetor manual is indispensable for effective maintenance and repair. It provides detailed instructions, diagrams, and troubleshooting guides, ensuring accurate adjustments and fixes. Without the manual, mechanics risk incorrect jetting, improper assembly, or overlooked steps, leading to poor performance or engine damage. The manual covers critical processes like cleaning, jetting calibration, and rebuild procedures, making it a vital resource for both novice and experienced technicians to keep their carburetors functioning optimally.

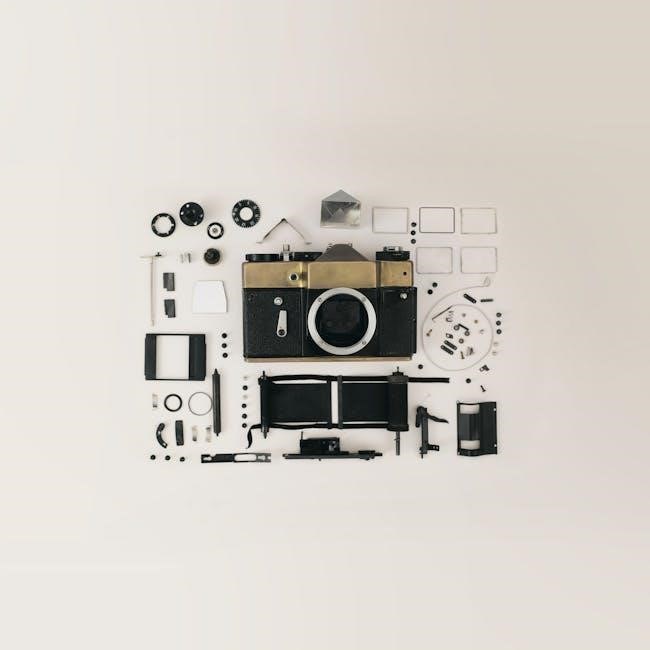

Key Components of the Keihin Carburetor

The Keihin carburetor comprises essential parts including the throttle valve, main jet, pilot jet, and float system, each playing a vital role in airflow and fuel delivery for optimal engine performance.

2.1 Throttle Valve and Its Function

The throttle valve in a Keihin carburetor controls airflow by rotating to regulate engine speed and performance. It operates by opening or closing to allow more or less air into the venturi, which directly affects the fuel flow through the main and pilot jets. Proper adjustment of the throttle valve ensures the correct air-fuel mixture, essential for smooth engine operation. Improper settings can lead to issues like poor idle or reduced power at higher speeds. Always refer to the manual for precise adjustment guidelines to maintain optimal performance and avoid potential engine damage.

2.2 Main Jet and Pilot Jet Explained

The main jet and pilot jet are critical components in a Keihin carburetor, responsible for delivering fuel at different engine speeds. The main jet controls fuel flow during high RPMs, ensuring proper combustion at wide throttle openings. The pilot jet, on the other hand, regulates fuel supply at low speeds, maintaining a smooth idle. Proper sizing and adjustment of these jets are vital for optimal performance, as incorrect settings can lead to poor engine response or inefficient fuel consumption. Always consult the manual for precise tuning guidelines to achieve the ideal air-fuel mixture.

2.3 Understanding the Float System

The float system in a Keihin carburetor is designed to maintain the optimal fuel level in the float bowl. It consists of a float and a needle valve, which work together to regulate fuel flow from the fuel tank. When the float rises with the fuel level, it closes the needle valve to prevent overflow. Conversely, as fuel is consumed, the float drops, opening the valve to refill the bowl. Proper adjustment of the float system ensures consistent fuel delivery, preventing issues like flooding or starvation. Regular inspection and cleaning are essential to maintain its functionality and overall carburetor performance.

Troubleshooting Common Issues

Troubleshooting common issues with the Keihin carburetor involves identifying symptoms like poor performance or a lean bog. Use a flow chart for systematic diagnosis and effective solutions.

3.1 Identifying Symptoms of Poor Performance

Common symptoms of poor performance in Keihin carburetors include rough idling, hesitation, and backfiring. These issues often stem from improper jetting, clogged passages, or vacuum leaks. A noticeable “lean bog” during acceleration is another key indicator, suggesting an air-fuel mixture imbalance. Riders may also experience reduced power or inconsistent throttle response. Diagnosing these symptoms early is crucial to prevent further damage. Using a vacuum gauge or flow chart can help pinpoint the root cause, guiding effective repairs outlined in the manual.

3.2 Addressing the Lean Bog Issue

A lean bog occurs when the air-fuel mixture becomes too lean, causing engine hesitation or stumbling during acceleration. This issue often arises from clogged pilot jets or improper jetting setups. To resolve it, ensure the pilot jet is clean and functioning correctly. Adjusting the air-fuel mixture by enriching the fuel flow can also help. Consulting the manual’s troubleshooting section or using a flow chart can guide precise adjustments. Additionally, checking for vacuum leaks and ensuring proper throttle shaft alignment are crucial steps to eliminate the lean bog effectively.

3.3 Using a Flow Chart for Effective Troubleshooting

A flow chart is a valuable tool for systematically diagnosing and resolving carburetor issues. By following a structured approach, users can identify symptoms, trace causes, and apply targeted solutions. This method saves time and reduces guesswork, ensuring accurate repairs. Flow charts often cover common problems like lean bogs or poor idle, guiding users through steps like cleaning jets or adjusting mixtures. They also help in customizing jetting and needle setups for specific engine modifications, enhancing overall performance and reliability.

Maintenance and Cleaning Guide

Regular maintenance and thorough cleaning are crucial for optimal carburetor performance. Use a toothbrush and solvent to scrub interior surfaces, ensuring all passages are clear. Prevent corrosion with proper storage and protect components from debris. Follow a detailed cleaning schedule to maintain reliability and peak engine performance.

4.1 When and How to Clean the Carburetor

Regular cleaning is essential to maintain optimal performance. Start by disassembling the carburetor and soaking components in a solvent. Use a toothbrush to scrub internal surfaces, paying attention to small passages. Avoid scratching delicate parts. After cleaning, dry thoroughly and reassemble. Always consult the manual for specific instructions tailored to your Keihin model. Clean the carburetor every 1,000 to 3,000 miles or when performance issues arise. Proper cleaning ensures smooth operation and prevents fuel flow restrictions.

4.2 Step-by-Step Rebuild Process

Start by disassembling the carburetor, carefully labeling all components. Use a rebuild kit to replace worn parts like gaskets, jets, and needles. Inspect and clean all passages before reassembly. Ensure the float system is properly aligned and functional. Reinstall components in the reverse order of disassembly. Tighten all screws and bolts securely. Refer to the manual for torque specifications and alignment guides. After reassembly, test the carburetor for leaks and proper function. Rebuild kits are widely available online, with guides like the Mikuni tuning manual offering additional insights.

4.3 Tips for Preventing Corrosion and Damage

Apply vacuum grease to throttle shafts to prevent wear and corrosion. Regularly inspect and replace worn-out components to avoid damage. Use a soft brush and mild solvent for cleaning to prevent scratching surfaces. Store disassembled parts in a dry, protected environment. Avoid using harsh chemicals that can degrade rubber or plastic components. Refer to rebuild kits and manuals for specific part replacements. Proper maintenance ensures long-term functionality and performance of your Keihin carburetor.

Jetting and Calibration

Jetting and calibration ensure optimal engine performance by adjusting fuel flow through jets and needles. Proper setup enhances power delivery, efficiency, and reliability, tailored to specific engine configurations.

5.1 Choosing the Right Jet and Needle Setup

Selecting the appropriate jet and needle setup is crucial for optimal performance. Jets regulate fuel flow at different throttle openings, while needles fine-tune the mixture. Factors like engine modifications, air filters, and exhaust systems influence choices. Consulting a jetting chart or flow chart helps determine ideal configurations. Experimentation may be needed to achieve the perfect balance, ensuring smooth power delivery and efficient combustion across the RPM range.

5.2 Adjusting for Optimal Air-Fuel Mixture

Adjusting the air-fuel mixture ensures your engine runs efficiently. Start by setting the idle mixture screws to spec, then fine-tune for smooth operation. Use a vacuum gauge to guide adjustments, aiming for peak RPM. Richening the mixture may be needed for high-performance setups, while leaning it can improve fuel efficiency. Always test adjustments incrementally and monitor engine response to avoid damage from improper settings.

5.3 Tuning Guide for Different Engine Modifications

Engine modifications require precise carburetor tuning. For increased performance, consider upgrading jets and adjusting needle positions. High-compression engines may need richer mixtures, while modified exhausts could demand leaner settings. Use flow charts or spreadsheets to calculate ideal jet and needle setups. Test adjustments incrementally, monitoring performance gains and avoiding over-rich or lean conditions that could harm the engine. Always refer to community resources or forums for proven configurations specific to your modifications.

Repair and Replacement

Identify faulty components like throttle shafts or vacuum seals. Replace worn parts with genuine rebuild kits. Ensure proper installation to maintain optimal carburetor performance and engine efficiency.

6.1 Fixing Throttle Shaft Issues

Throttle shaft problems often arise from wear or corrosion, leading to air leaks or poor throttle response. Start by disassembling the carburetor and inspecting the shaft for damage. Clean the shaft and surrounding area with a carburetor cleaner. If worn, replace the shaft seal or the entire throttle shaft assembly. Apply vacuum grease to ensure a tight seal. Proper installation is crucial to avoid vacuum leaks and maintain smooth throttle operation. Refer to online forums for detailed repair guides and rebuild kits specifically designed for Keihin carburetors.

6.2 Repairing Vacuum Leaks

Vacuum leaks can cause poor engine performance, rough idling, and decreased fuel efficiency. Start by inspecting the carburetor-manifold connection for loose bolts or damaged gaskets. Use a vacuum gauge or smoke test to locate the leak. Replace any worn O-rings or gaskets, and ensure all connections are tightened to the specified torque. Apply a gasket sealer for extra protection. Avoid temporary fixes and opt for a thorough inspection to ensure a proper seal. This will restore optimal airflow and engine performance.

6.3 Replacing Worn-Out Components

Replacing worn-out components ensures optimal carburetor performance and prevents further damage. Common parts to replace include the throttle shaft, jets, and gaskets. Use high-quality rebuild kits for reliability. Always refer to the manual for correct part numbers and installation steps. Inspect components regularly to identify wear early. Proper replacement restores airflow and fuel efficiency, ensuring smooth engine operation.

Resources and Further Reading

Explore forums, manuals, and guides for detailed insights. Rebuild kits and parts are available online, ensuring proper maintenance and upgrades for optimal carburetor performance and longevity.

7.1 Recommended Forums and Communities

7.2 Additional Manuals and Guides

Beyond the Keihin Carburetor Manual PDF, the MikuniCarbTuningManual is a valuable resource for comparative insights. Websites like KZRider offer detailed guides and spreadsheets for jet and needle setups. Additionally, forums often share user-created repair guides and troubleshooting flow charts. These resources complement the official manual, providing practical tips and real-world applications for enthusiasts and mechanics working with Keihin carburetors.

7.3 Where to Find Rebuild Kits and Parts

Rebuild kits and parts for Keihin carburetors are widely available online. Websites like eBay and specialty motorcycle shops offer genuine and aftermarket components. Forums such as KZRider often provide detailed threads on sourcing parts. When purchasing, ensure compatibility with your specific carburetor model. Kits typically include gaskets, jets, and seals. Always verify seller reviews and part authenticity to avoid counterfeit items.