Industrial electrical schematics are detailed diagrams representing electrical circuits and components in industrial systems․ They are essential for designing, troubleshooting, and maintaining electrical installations․ Understanding these schematics ensures safe and efficient system operation, helping technicians identify components, trace circuits, and diagnose issues․ A comprehensive guide, such as a how to read industrial electrical schematics PDF, provides step-by-step explanations and practical exercises for mastering schematic interpretation․

1․1 What Are Industrial Electrical Schematics?

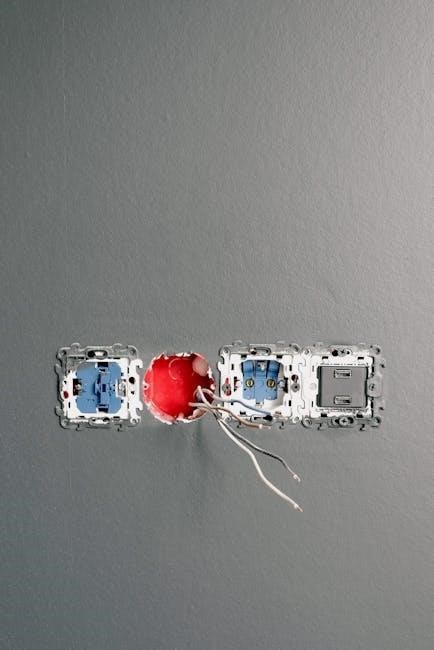

Industrial electrical schematics are detailed diagrams that visually represent electrical circuits, components, and systems in industrial settings․ They use standardized symbols to illustrate how power flows through systems, connecting devices like sensors, motors, and control units․ These diagrams are essential for designing, troubleshooting, and maintaining complex electrical installations, ensuring safe and efficient operations․

1․2 Importance of Understanding Electrical Schematics

Understanding electrical schematics is crucial for ensuring safety, efficiency, and proper system maintenance․ It enables technicians to diagnose issues, optimize performance, and comply with safety standards․ Proficiency in reading schematics enhances troubleshooting, reduces downtime, and minimizes risks, making it a fundamental skill in industrial electrical work and system management․

1․3 Basic Concepts and Terminology

Mastering basic concepts and terminology is essential for interpreting industrial electrical schematics․ Key elements include understanding symbols, circuits, voltage, current, and components like resistors, capacitors, and transformers․ Familiarity with terms ensures clear communication and accurate analysis, forming the foundation for advanced schematic reading and troubleshooting in industrial settings effectively․

Understanding Symbols and Components

Understanding symbols and components is crucial for interpreting industrial electrical schematics․ Standard symbols represent devices like motors, relays, and transformers, ensuring clarity and consistency in circuit design and troubleshooting․

2․1 Standard Electrical Symbols

Standard electrical symbols represent components like resistors, capacitors, and inductors in schematics․ These symbols ensure consistency and clarity in circuit design․ Common symbols include those for motors, transformers, and relays․ Understanding these symbols is essential for accurately interpreting industrial electrical schematics and troubleshooting efficiently․ Guides like the how to read industrial electrical schematics PDF provide detailed explanations․

2․2 Common Components in Industrial Schematics

Common components in industrial schematics include motors, transformers, relays, circuit breakers, and PLCs․ These elements are fundamental for understanding and maintaining industrial electrical systems; They ensure safe and efficient operation, enabling technicians to troubleshoot effectively․ A guide like the how to read industrial electrical schematics PDF provides detailed overviews of these components․

2․3 Labeling and Identification of Components

Labeling and identification of components in industrial schematics are crucial for clear understanding․ Components are typically labeled with standard symbols and reference designators, ensuring consistency․ This allows technicians to quickly identify elements like transformers, motors, and relays․ Proper labeling aids in efficient troubleshooting and ensures accurate circuit analysis, as outlined in the how to read industrial electrical schematics PDF․

Types of Industrial Electrical Diagrams

Industrial electrical diagrams include wiring diagrams, line diagrams, and schematic diagrams․ Each type serves specific purposes, such as detailing connections, showing system relationships, or simplifying complex circuits for easier analysis․

3․1 Wiring Diagrams

Wiring diagrams provide detailed visual representations of electrical connections and circuits․ They illustrate the physical links between components, making it easier to install, troubleshoot, and maintain systems․ These diagrams are essential for understanding how devices are interconnected and for identifying potential issues in industrial electrical setups․

3․2 Line Diagrams

Line diagrams simplify complex electrical systems by illustrating circuit relationships using standardized symbols․ They focus on the logical flow of power and control signals rather than physical connections, making it easier to understand system hierarchy and identify circuit pathways efficiently․

3․4 Schematic Diagrams

Schematic diagrams provide detailed visual representations of electrical circuits, showing components, connections, and their functions․ They use standardized symbols to illustrate circuit pathways, voltage distribution, and control signals, enabling technicians to interpret and troubleshoot systems effectively․ These diagrams are essential for understanding complex industrial electrical systems and their operational logic․

Reading Techniques for Industrial Schematics

Mastering schematic reading involves identifying inputs, outputs, and power supplies, then tracing circuits to understand voltage distribution and control signals․ This foundation is crucial for effective troubleshooting and system maintenance․

4․1 Tracing Circuits and Identifying Pathways

Tracing circuits involves following the flow of electricity through components, identifying pathways, and understanding how they connect․ This process helps locate power sources, switches, and loads, enabling technicians to diagnose faults effectively․ Using tools like multimeters and circuit diagrams enhances accuracy in tracing and identifying pathways in industrial electrical systems․

4․2 Understanding Inputs, Outputs, and Power Supply

Understanding inputs, outputs, and power supply is crucial for interpreting industrial electrical schematics․ Inputs include sensors and controls, while outputs are devices like motors or lights․ The power supply provides the necessary voltage and current, ensuring all components function correctly․ Identifying these elements helps in troubleshooting and maintaining system efficiency․

4․3 Interpreting Voltage Distribution and Control Signals

Interpreting voltage distribution involves identifying how power is supplied across circuits․ Control signals, such as those from sensors or PLCs, dictate system operations․ By analyzing these elements, technicians can diagnose issues, ensure proper voltage levels, and verify signal integrity, which is critical for maintaining efficient and reliable industrial electrical systems․

Common Mistakes to Avoid

- Misreading symbols and components can lead to circuit errors․

- Ignoring safety procedures increases the risk of electrical hazards․

- Overlooking voltage and current ratings can damage equipment․

5․1 Misreading Symbols and Components

Misreading electrical symbols and components is a common mistake that can lead to incorrect circuit interpretations․ Ensure all symbols are cross-referenced with legends, and components are identified correctly․ Overlooking details like voltage ratings or terminal connections can cause errors in troubleshooting and repairs, emphasizing the need for thorough understanding and attention to detail․

5․2 Overlooking Safety Procedures

Overlooking safety procedures is highly dangerous and can lead to severe injuries or equipment damage․ Always turn off power supplies and use personal protective equipment (PPE) when working with electrical systems․ Ignoring safety protocols increases the risk of accidents, making adherence to established guidelines crucial for safe operations․

5․3 Ignoring Voltage and Current Ratings

Ignoring voltage and current ratings can lead to equipment damage or electrical fires․ Always verify the ratings of components and ensure they match system requirements․ Misjudging these specifications can result in dangerous overloads or malfunctions, emphasizing the importance of careful planning and adherence to electrical standards in industrial settings․

Troubleshooting Using Schematics

Industrial electrical schematics are essential tools for diagnosing issues in electrical systems․ They help identify faults, isolate problems, and guide efficient repairs, minimizing downtime and ensuring system reliability․

6․1 Identifying Faults in Electrical Systems

Industrial electrical schematics enable technicians to pinpoint faults by tracing circuits and identifying malfunctioning components․ By analyzing the flow of electricity and comparing it to the schematic, professionals can locate issues like short circuits, open connections, or faulty devices, ensuring accurate and efficient repairs․

6․2 Using Schematics for Diagnostic Purposes

Schematics are vital diagnostic tools, allowing technicians to visualize electrical systems and isolate faults․ By cross-referencing live readings with the diagram, professionals can identify discrepancies, verify component functionality, and systematically diagnose issues, ensuring efficient troubleshooting and minimizing downtime in industrial operations․

6․3 Tools and Techniques for Effective Troubleshooting

Essential tools include multimeters, circuit testers, and oscilloscopes for measuring voltage, current, and signal integrity․ Techniques involve tracing circuits, verifying connections, and simulating faults․ Systematic approaches, such as isolating sections and cross-referencing schematics, enhance accuracy and efficiency in identifying and resolving electrical system issues effectively․

Safety Considerations

Safety is crucial when working with electrical systems․ Always adhere to safety standards, use personal protective equipment, and ensure all safety protocols are strictly followed to prevent hazards․

7․1 Safety Protocols When Working with Electrical Systems

Adhering to safety protocols is critical when handling electrical systems․ Always de-energize circuits, use personal protective equipment (PPE), and follow lockout/tagout procedures․ Ensure only qualified personnel perform tasks, and strictly follow safety guidelines to minimize risks and prevent electrical hazards or injuries․

7․2 Understanding Hazardous Voltage Levels

Hazardous voltage levels pose significant risks to personnel and equipment․ Voltages above 50V AC or 120V DC are considered dangerous, capable of causing severe injury or death․ Always identify these levels in schematics and adhere to safety practices to prevent electrical shock or arc flash incidents․

7․3 Best Practices for Safe Electrical Work

Always de-energize circuits before work, use proper PPE, and follow safety protocols․ Verify voltage levels with test equipment, and never bypass safety devices․ Ensure proper tool insulation and conduct regular inspections․ Stay informed about industry standards and regulations to maintain a safe working environment and prevent accidents․

Practical Exercises and Examples

This section provides hands-on exercises, including step-by-step circuit analysis and troubleshooting․ Real-world examples and practice exercises reinforce learning, helping readers master schematic interpretation through practical application and repetition․

8․1 Step-by-Step Analysis of a Sample Schematic

This exercise guides readers through a detailed breakdown of a sample schematic, teaching how to identify components, understand their interactions, and trace circuit pathways․ It emphasizes recognizing power sources, control signals, and output devices, ensuring a clear understanding of the system’s functionality․ Practical exercises reinforce these concepts for hands-on learning․

8․2 Real-World Applications of Schematic Reading

Understanding industrial electrical schematics is crucial for troubleshooting, designing, and maintaining electrical systems․ Real-world applications include installing machinery, diagnosing faults, and optimizing production processes․ Schematics guide technicians in power plants, manufacturing, and automation, ensuring efficient and safe operations․ Practical examples in PDF guides illustrate how to apply schematic reading skills in industrial environments effectively․

8․3 Practice Exercises for Reinforcing Learning

Practice exercises are essential for mastering industrial electrical schematics․ They include analyzing diagrams, identifying components, and tracing circuits․ Exercises in PDF guides help reinforce understanding by applying theoretical knowledge to real-world scenarios, ensuring proficiency in reading and interpreting schematics effectively․

Resources for Further Learning

Recommended guides, online courses, and communities provide in-depth knowledge on reading industrial electrical schematics․ These resources offer practical tutorials and expert support for continuous learning and skill improvement․

9․1 Recommended PDF Guides and Tutorials

PDF guides and tutorials offer detailed step-by-step explanations for reading industrial electrical schematics․ They cover essential topics such as standard symbols, circuit analysis, and troubleshooting techniques․ These resources are designed to cater to both beginners and advanced learners, providing practical exercises and real-world examples to enhance understanding and application of schematic reading skills effectively․

9․2 Online Courses and Training Programs

Online courses and training programs offer structured learning paths for mastering industrial electrical schematics․ They cover topics like electrical symbols, circuit analysis, and troubleshooting․ Many include quizzes, hands-on exercises, and real-world applications․ Platforms like Coursera and Udemy provide accessible training, suitable for both beginners and experienced professionals․ These courses enhance practical skills and knowledge effectively․

9․3 Communities and Forums for Support

Online communities and forums provide valuable support for learning to read industrial electrical schematics․ Platforms like Reddit’s r/LearnElectronics and specialized forums such as All About Circuits offer discussions, troubleshooting tips, and resources․ Engaging with these communities connects you with experienced professionals and provides real-world insights and examples to enhance your learning journey․

Mastery of industrial electrical schematics requires practice and dedication․ By following guides like a how to read industrial electrical schematics PDF, you’ll gain the skills to analyze and troubleshoot complex systems effectively․ Keep practicing to refine your expertise and stay updated with industry advancements for continuous improvement․

10․1 Summary of Key Concepts

Mastering industrial electrical schematics involves understanding symbols, components, and diagrams․ Key concepts include tracing circuits, identifying pathways, and interpreting voltage distribution․ Safety protocols and troubleshooting techniques are crucial․ Regular practice and real-world application reinforce learning, enabling efficient diagnosis and maintenance of complex electrical systems․

10․2 Encouragement to Continue Practicing

Consistent practice is essential for mastering industrial electrical schematics․ Regularly engaging with real-world diagrams and troubleshooting scenarios enhances proficiency․ Staying updated with industry standards and advancements ensures long-term competence․ Joining communities and seeking feedback can further refine skills, leading to expertise in interpreting complex electrical systems․

10․3 Final Tips for Mastering Industrial Electrical Schematics

Mastering industrial electrical schematics requires dedication and hands-on practice․ Start by identifying key standards and symbols, then cross-reference with wiring diagrams․ Use diagnostic tools and manufacturer data for accuracy․ Regularly test your understanding with practice exercises․ Stay updated with industry advancements to maintain long-term proficiency and adapt to new technologies․